In the Beginning...

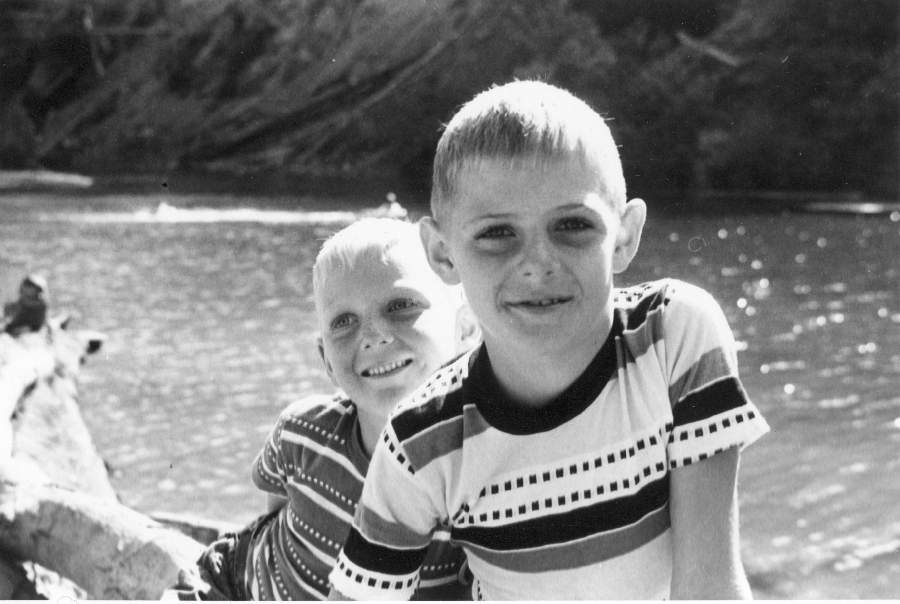

Greg Heet, inventor of the EBow.

I first met electricity as an infant in the year of my birth, 1947. My mom was bathing me in the kitchen sink when the electric clock sitting nearby fell into the water. We were both shocked as my mom plucked me from the bath, falling backwards onto the floor. That would be the first of many thrilling but harmless electrocutions over my lifetime.

As a curious toddler, I managed to find one of my mom’s hairpins and insert it into an electrical outlet. I made the connection and managed to burn a hole in my hand. One day, my mom returned to the living room to find I had removed some screws from our vacuum cleaner. My reverse engineering life had begun.

First Invention

As a preteen, I enjoyed shocking my family members, especially my little brother, with the static electricity that came from shuffling across the carpet in the warm, dry summer days of Southern California. Since I was allowed a little workshop in the garage, I worked on my very first invention, a portable people shocker. It consisted of a piece of carpet wrapped around a large tube that could be rotated with a crank. A shoe rested on the carpet as I cranked it round and round, but I could get no spark. Apparently, a human foot was required. While not successful, my modus operandi was established. Not so much inventing as experimenting, trial-and-error, the method I used to later ”discover” the ebow. In that little workshop, I also built my first crystal radio and played with a chemistry set that had flamable metal strips and toxic chemicals. Those were the days.

Vibes and Organ played by Guitar

My first musical invention was in the mid ‘60s. I hand-wrapped insulated wire around thirty-seven ¼” diameter tubes and placed them under the bars of a three-octave vibraphone. Thirty-seven 3” nails, resting on a shelf, sat partially in the tubes and when I applied electricity to the coils, the nails would act like a solenoid and strike the bars. I found some surplus pushbutton switches and mounted them on a no-parking sign I had drilled out. The switches were arranged in a guitar fretboard configuation, six wide and ten long.

You could finger a guitar chord by pressing the switches and play the vibraphone. I found a surplus sign flasher, like the ones used to sequentially flash liquor store lights and used that to automatically arpeggiate the chord I was holding. Later, I bought an old organ for $50, took it apart and had my guitar switches activate that as well. I could play vibes and organ with my guitar configured switches.

Voicitar

It all began in the late '60s when, one day, I sang into the sound hole of an acoustic guitar and different strings would vibrate when I sang notes that matched their frequency. I mounted a speaker over the strings to see if singing into a mic, through an amplifier, connected to that speaker would also drive the strings. It did. This was the birth of an instrument I called the Voicitar. I was learning to play sitar at the time at Ravi Shankar’s Kinnara school of music in Los Angeles.

The first and only recording of the Voicitar was by the Scotish psychedelic folk group called the Incredible String Band in a song called Invocation, released in 1969:

Voicitar >>> EBow principle

I knew nothing about electronics but was quite the trial-and-error experimenter. An acquaintance gave me several stereo tape heads. I took a 5-foot long 2x6 redwood board and mounted six stereo tape heads over 12 guitar strings tuned to a scale. I ran a microphone into my 40-watt Fender Bandmaster amp then directly into the tape heads.

The strings rang out when I would sing their respective pitches. It was like a glorified reverb as the strings would continue to ring for a time as I moved to another pitch. Low notes sounded like a bowed cello. At one point, I hung the microphone out of my upstairs window and as cars drove by, my Voicitar would play beautiful random music which I would let play for hours, turning street noise into music.

The Voicitar had an input for the microphone and an output which was just a guitar pickup under the strings. One day, I plugged the output into the input and the strings began to vibrate themselves. Voilà! The EBow principle was born.

The First 6-string EBow

Along the way, I read that there were just coils in those tape recorder heads, so I replaced them with self-wound coils wrapped around nails as their core. This worked reasonably well but did not have much drive. I also loved magnets (of course) and I stuck one on the back of these cores and the drive increased many-fold. Golly gee. Nobody told me.

I then built a six-string version with six driver coils using the guitar pickup as the input. This was a little uncontrollable so I added six push buttons to determine which string would be driven and ring out. It was possible but difficult to get more than one string to vibrate at a time. It would work for a moment and then one string would take over and the other would die out. You had to rock back-and-forth between two buttons to keep both strings sustaining.

Eventually, I transitioned to separate circuits for each string. Each lived in its own little world. Later, I added a threshold to each of the six circuits so that each string would activate and sustain only when tapped or plucked and quickly mute when that string was manually muted.

For that early six-string version, I was using a surplus Sears replacement circuit consisting of 5 transistors (remember those?). I still did not know electronics but was beginning to connect with electronic consultants. While I was busy trying to figure out what transistors Sears used so that I could re-create their surplus amp, a consultant suggested I might use an integrated circuit (IC). I believe these were fairly new at the time. They were certainly new to me. I remember raving in our early EBow advertisements that the EBow had 13 transistors as this is how transistor radios were promoted. Of course, those transistors were actually within the integrated circuit, but I was still proud that we were making use of 13 of them. Switching to this integrated circuit made the whole package very small. Small enough that I thought maybe we could make this Energy Bow, as we called it at the time, portable! Another breakthrough!

Hand-held EBow

I made a single channel Energy Bow consisting of a pickup coil, an integrated circuit and a drive coil along with the battery. I embedded the whole thing in epoxy and when you held it over a guitar string, the string rang out. At this point my friends were saying you’re going to make a million dollars. Little did I realize how much work lay ahead.

I took this little potted prototype to the Guitar Center on Sunset Boulevard in Hollywood and subtly began driving a string on a displayed acoustic guitar. Patrons and a clerk took notice and wandered over to see “What the heck?”. I remember the clerk, who chose not to be surprised, calmly said “Oh yeah, I know about those” even though I held in my hand the only one in existence.

This early EBow had no foot so it was very difficult to hold in place at just the right angle to drive the string. It had to be aligned in three different axes to work and held just barely off the string. It had to align with the strings, be very close to the strings, and not be tilted for it to drive the string into sustain. There was no way it could be easily played without focusing intensely on this alignment. The oh-so promising hand-held EBow went back on the shelf as impractical.

The First EBow Foot

I continued to work on the in-built, non-portable, 6-string version when one night it hit me! Why not rest it on the adjacent (non-driven) strings and add grooves to achieve alignment in 3 axis and (bonus points) allow it to be slid along the strings for dynamic control. Thus, the hand-held EBow you see today was born.

Pictured, an early prototype testing this idea.

The Final EBow Foot

It took many more months of trial-and-error to design the perfect foot that would not slip between the strings when crossing and would feed the next string under the foot for a smooth travel across the strings locking into place over each string as it crossed.

Chrome EBow

The very first model released at the NAMM show in Chicago in the summer of 1976 turned on automatically when placed over the string and shut off when removed. This feature took five transistors in addition to the integrated circuit. Now we had it all. Transistors AND an integrated circuit. I impressed myself.

In the year-long design process determining the final shape and making a mold, my design consultants showed me a chrome plated keychain they had just designed, and I said, “Stop the presses! The EBow has to be chrome.” Well, that certainly extended the timeline as this introduced many problems, the worst of which was the warping of the plastic parts due to the heated baths necessary for the chrome plating. Copper then nickel then chrome. What a nightmare, but it all worked out eventually. Now, instead of just simply gluing the housing pieces together, we had to design a way to sand away the chrome on the edges to expose the glue-able plastic. Boy, if I had it to do over, I might have skipped the chrome.

EBow Holster

In another move to make things more difficult, I decided to make a custom leather holster for the EBow. I found a surplus press and had dies made to squeeze 1/4” leather into the holster shape. It was challenging as it required opposing 90-degree bends nearly two inches deep. We clicked out the two leather pieces, soaked and reshaped them using heated dies, had them stitched up and dyed, then added the snaps. I sometimes question my judgement as this process was even more difficult than making the EBow itself. This chrome EBow in its black derringer holster brought its own problems as we tried to get them through airport security.

Our First NAMM Show

We worked hard building our own custom booth for the 1976 NAMM show in Chicago where the EBow made its first public appearance. I remember working through the night before the show, perfecting the prototypes we would demonstrate the next day.

We were a hit at the show. Jerry Garcia was our very first customer and he bought three. The Gizmotron people (a project spearheaded by half of the group 10cc (called 5cc), approached us at the show warning us that they soon would have a product that woud be in direct competition with the EBow. The Gizmo was a mechanical bowing device that mounted on the bridge of the guitar. When I returned from the show, I made my own “hand-held” gizmo I called the WizBow.

Potted Electronics

I had worked most of the night finalizing the circuit for the trade show. It would be months before we actually produced our first models. This prototype was not potted and was certainly vulnerable to impact. When a customer dropped the prototype, my demonstrator picked it up and lo-and-behold, it still worked, or so I thought. After proving to the customer that it was durable, Joel turned to me and said, it’s not working. He had just used exaggerated vibrato to keep the string vibrating.

We potted the electronics after that. I remember throwing an early potted test EBow out of my second story window onto the pavement below and celebrating the fact that it still worked. It was mangled, of course.

Later Models

A few years later, we eliminated the chrome in favor of a much better self-lubricating plastic that glides silently and effortlessly along the strings. We also dropped the 5 transistor auto-switch portion of the circuit since 95% of our rejects were due to this feature.

At one point, my brother and his family were making the ebows when, for some reason, he licked the back of the electronics and noticed an increase in drive. After analyzing exactly what he had done, we added parts to approximate his discovery and thereafter produced a much-improved model which we fondly nicknamed the licked-circuit model. This improvement is employed today. Thank you, Larry (and family).

There have been several ebow models over the years. Our latest (2024) is the most sensitive and easiest to control model yet for super fast response and a killer tone. I’m working on other improvements and variations so I must now return to my lab. My workbench is calling.